Why WAT – Water Activated Tape

Water activated tapes are manufactured on High Strength Virgin Kraft Paper and have a Vegetable Starch based adhesive for packaging and sealing purpose of Corrugated Boxes. They need to be moistened (with water) for activation and form a very strong, unbreakable bond with the surface of the Corrugated or Fibre Board box.

For eco minded customers committed to sustainability it is our recommendation to always use WAT. It is made of paper which is a natural, renewable product, and the vegetable adhesive is natural, 100% eco-friendly and bio-degradable as well. Means it can be recycled and re-pulped along with the boxes it is adhered to, without any time consuming stripping.

It also ranks much higher on the eco obvious scale which means people easily recognize it as a Green Product, especially compared to BOPP/Plastic tape. It is the “eco consistent” way to seal your green boxes, filled with green products for your green minded customers.

Simply put, WAT does a better job compared to BOPP/Plastic tape. The vegetable adhesive on WAT is not only natural; it also bonds aggressively to the corrugated box, especially even if the box is under-filled. Gummed Paper Tape penetrate right into the liner of the carton, creating a total bond. The tape has become part of the carton and adds strength to it, i.e. a magnificent & best box closing method.

Gummed Paper Tape cannot be removed from the carton without leaving traces of damage or pilferage. Such a box closure provides protection against theft and pilferage. We have all seen cases where the tape is virtually suspended over the box flaps and is not making any real contact with either major case flap. That is not good for many reasons, including pilferage, damage and even infestation. In case of the box having Food Products, Medicines, Baby Products, etc it is a very serious matter, and WAT over comes that.

WAT is not at all affected by extreme hot or cold temperatures and works well in humid and dusty conditions. Compared to BOPP/Plastic tape WAT adheres better to the rough surface of Corrugated Boxes (they having low energy, made of recycled fibres). WAT has an advantage with its coating surface being cracked which helps it bonding well at edges and corners of the boxes being sealed.

And, WAT compared with BOPP/Plastic tape has complete noiseless application, with no noise generated while its release and application.

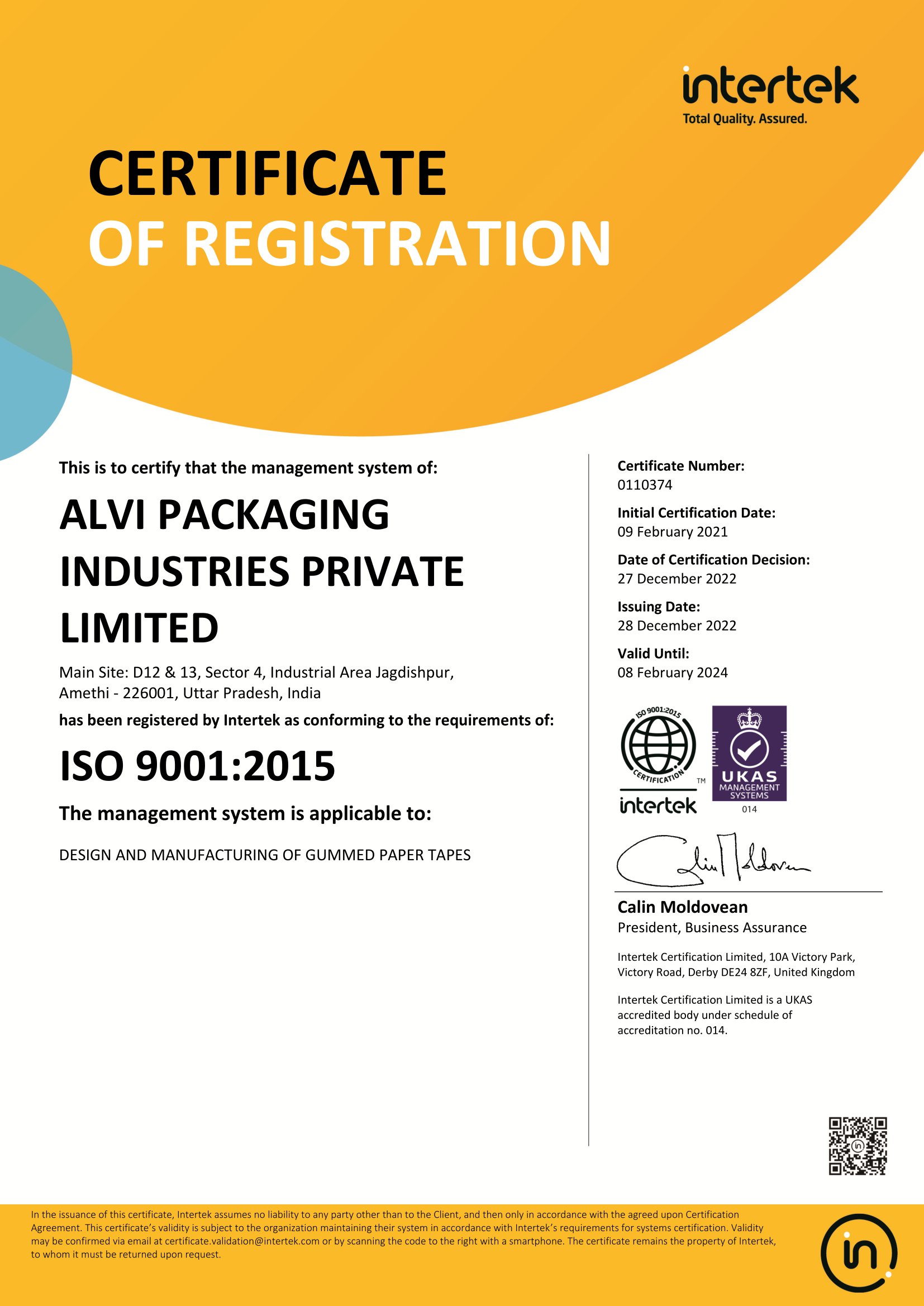

Alvi Packaging Industries P. Ltd. has been in Gummed Paper Tape manufacturing from the past 36 Years.